Quick Summary:

ExxonMobil – one of the world’s largest producers of isopropyl alcohol (IPA), a key ingredient in medical hand sanitizer – is pivoting its business to make medical hand sanitizer for U.S. military personnel and medical first responders.

An ExxonMobil team of experts is offering their experience to help a collaborative effort organized by the Global Center for Medical Innovation. This collaboration, which represents industry, academia and government, is rethinking how protective medical equipment, specifically face shields and face masks, is made. The collaboration has also produced models for a new, reusable face mask design that will address the shortage of N95 protective masks.

ExxonMobil is working to help meet the needs of health care professionals fighting the COVID-19 pandemic on the front lines, as well as those socially distancing themselves at home. While those needs continue to evolve, the company remains focused on working to meet global energy demand. Below are just some examples of what ExxonMobil is doing to help fight COVID-19.

Protecting travelers and TSA officers

To protect travelers and Transportation Security Administration (TSA) officers during the COVID-19 pandemic, TSA needed thousands of gallons of disinfectant – and they needed it quickly. Thanks to close coordination between ExxonMobil, one of the largest producers of isopropyl alcohol, a key sanitizer ingredient, and Univar Solutions, one of the largest chemical distributors, the surface disinfectant was produced and distributed to TSA in record time, in just days, rather than the weeks it would have taken before the pandemic.

ExxonMobil is increasing production of IPA to help meet higher demand resulting from the pandemic. Its chemical plant in Baton Rouge, Louisiana, has recently been able to achieve an increased monthly production level which equates to enough IPA to supply a monthly equivalent of nearly 50 million 4-ounce bottles of medical-grade sanitizer.

The scale and urgency of TSA’s request required detailed planning and a finely tuned logistics supply chain to manufacture, package and rapidly deliver the product to airports around the country.

From the Baton Rouge facility, the IPA was shipped to Univar Solutions’ packaging plant in Conroe, TX. From there the disinfectant was mixed, bottled and swiftly shipped north to TSA’s distribution facility near the Dallas-Fort Worth International Airport.

That disinfectant is now being distributed to airports nationwide, helping keep travelers, medical personnel and TSA officers safe. And ExxonMobil continues to maximize production of isopropyl alcohol and other important products needed to combat COVID-19 in communities across the country.

Maximizing supply of IPA—key ingredient in medical hand sanitizer

When it comes to fighting the COVID-19 pandemic, it doesn’t matter the size of the company. Everyone has a role to play.

For ExxonMobil – one of the world’s largest producers of isopropyl alcohol (IPA), a key ingredient in medical hand sanitizer – it means getting the product to where it’s needed most. For E.T. Browne – the small, family-owned manufacturer of Palmer’s® personal care products – it means pivoting its business to make medical hand sanitizer for U.S. military personnel and medical first responders.

The decision to repurpose its factory in East Stroudsburg, Pennsylvania, from making lip balm and body lotion to making hand sanitizer wasn’t the hardest part for E.T. Browne. It was obtaining key ingredients like IPA, which is in high demand due to the global emergency. Without IPA, E.T. Browne would not only be unable to make the hand sanitizer, but it also faced the prospect of shutting down its factory, which employs nearly 300 workers. That’s when ExxonMobil, whose Baton Rouge chemical facility is home to the world’s largest plant producing IPA, agreed to help.

ExxonMobil is maximizing its supply of IPA and other chemical products used in making a range of essential tools in the fight against COVID-19. ExxonMobil is also planning donations to other area hospitals. For ExxonMobil, supplying isopropyl alcohol is standard business, but doing so in this case required a swift response and a high priority.

Isopropyl alcohol is just one of many products helping to keep medical workers safe and people healthy. IPA, as an effective disinfectant, can be found in hand sanitizers, alcohol wipes and disinfectant sprays – products that are important in fighting the spread of COVID-19.

Thanking Houston-area COVID-19 responders with meals, masks

ExxonMobil is providing thousands of meals and medical face masks for Houston-area health care workers, police officers and firefighters responding to the COVID-19 pandemic, in a new initiative that brings total contributions for Houston-area relief to $450,000.

ExxonMobil is contributing $100,000 for personal protective equipment, such as medical masks, to Texas Medical Center member hospitals, the Houston Police Foundation, the Fire Fighters Foundation of Houston and the Spring Fire Department.

Another $100,000 will go to the TX Restaurant Relief Fund for the preparation and delivery of approximately 6,000 meals for frontline workers at these organizations. Prominent Houston chefs will participate in the effort that will enable participating restaurants to bring needed work to furloughed staff. The Texas Restaurant Association’s nonprofit arm established the TX Restaurant Relief Fund last month to provide immediate financial support to the state’s independent restaurateurs and their employees who have been heavily impacted by the loss of business due to COVID-19.

The support comes in addition to its recent contribution of $250,000 to the Houston Food Bank and Montgomery County Food Bank to provide about one million meals to Houston-area residents.

ExxonMobil, which has about 11,000 employees living and working the greater Houston area, remains focused on keeping its workforce safe and healthy to maintain its operations and maximize production of materials critical to the global response.

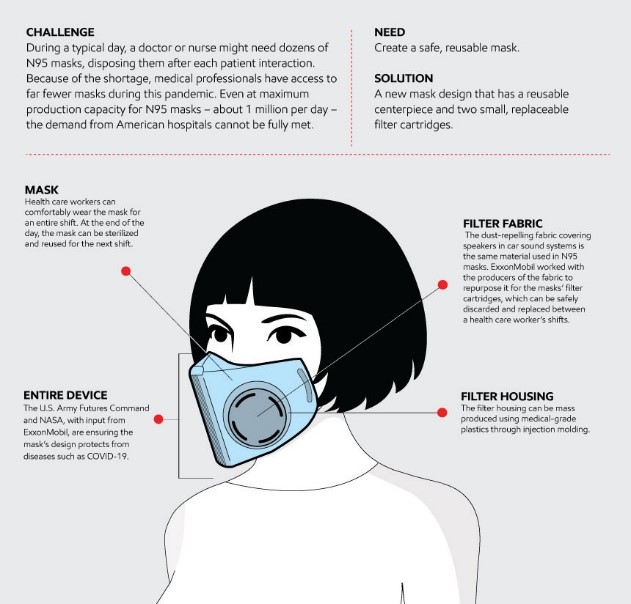

Addressing Face Mask Shortages

An ExxonMobil team of experts in chemicals, materials science and manufacturing is offering their experience to help a collaborative effort organized by the Global Center for Medical Innovation. By quickly connecting its customers to solution providers, ExxonMobil helped create a new supply chain to respond to the medical needs in hospitals across the country.

This collaboration, which represents industry, academia and government, is rethinking how protective medical equipment, specifically face shields and face masks, is made. All this happened in just a matter of days. So far, 50,000 face shields have been produced, and production facilities are ramping up to manufacture upwards of 170,000 more per hour in the coming days. The collaboration has also produced models for a new, reusable face mask design that will address the shortage of N95 protective masks.